Enhancing Food Safety with Proper Tool Care, Maintenance & Storage

Proper care, maintenance and storage of food contact tools is critical for ensuring a sanitary and code-compliant facility. In this blog, we’ll discuss the importance of tool maintenance, the basics on how to properly clean and store items, and how to identify when it is time for replacement.

Why Tool Maintenance Matters

Tool cleaning and storage protocols are essential to food safety, compliance, functionality, and for maximizing your investment. Following the correct procedures can prevent contamination, cross-contamination, ensure best performance, and prolong the life of your tools. Regular inspections and attention to potential signs of wear are equally important because damaged or worn-out tools lose hygienic attributes and effectiveness.

A food facility study by Camden BRI took Listeria samples and determined that the source of contamination was cleaning tools 47% of the time (drain brushes were 25% and floor cleaning tools 17%). Cleaning tools are notorious for being microbiological “collectors” so keeping your tools clean, dry and stored properly is critical.

Cleaning Your Tools

Food Safe Plastic Tools

The use of color-coded, FDA-compliant plastic tools is both strategic and effective. The industrial grade polypropylene plastic is durable and hygienically designed, making them long lasting and easy to clean. The ability to color-code with these tools is an essential element of HACCP plans, offering a variety of benefits -- the prevention of cross-contamination being the most important.

Cleaning materials: To avoid damaging the plastic surface, test the abrasiveness of the cleaning materials and avoid using metal scrapers or wire brushes. Scratches or gouges can compromise the sanitary nature of the plastic, making it difficult to fully clean. Also, use approved cleaning agents to ensure that the color of the tools will not be compromised.

Pre-Cleaning: Ensure your tools are free from food residues (often referred to as gross debris) before starting the cleaning process. This step, which can include rinsing, soaking and removal of debris, will make the cleaning process more effective.

Washing/Disinfecting: Rinse with water to make sure all debris is removed, then use water and a mild chemical cleaner or detergent appropriate for the plastic tools, according to industry standards. Be sure the tools are thoroughly washed until visibly clean and rinse well until all chemicals/detergents are removed (unless a particular cleaner is designed as “non rinsing”). Make sure none of the cleaning agents make their way into food processing cycles.

Sterilization: Sometimes sterilization is recommended or required as part of the cleaning process. The use of an autoclave, for example, may be needed to sterilize by heating tools at a certain temperature and pressure for a set time. To ensure sterilization, follow suggested guidelines.

Drying: Dry the tools immediately to prevent bacteria growth.

Stainless Steel Tools

Stainless steel is strong, durable and resistant to both corrosion and heat, making stainless steels tools a top choice in food processing. Type 304 stainless steel and Type 316 stainless steel are most commonly used, with type 316 preferred for environments with high chloride exposure (like salts).

Cleaning materials: To avoid damaging the surface, non-abrasive and non-scratching cleaning tools like sponges or soft cloths are ideal. Avoid using bristles that are too stiff, metal scrapers or wire brushes. Scratches and dents can compromise the sanitary and corrosion resistant surface of stainless steel. It’s recommended to clean a test spot in a non-critical area to ensure the stainless steel is being cleaned with damage.

Pre-Cleaning: As with plastic tools, remove any residual solids from your tools. Again, this step, which can include rinsing, soaking and careful removal of debris, will make the cleaning process more effective.

Washing/Disinfecting: Use warm water with a mild detergent or stainless steel cleaner to wash stainless steel tools. Best practice is to wipe with the grain of the metal. Rinse well with water to remove any cleaning agents from the surface and dry well, if not disinfecting next (water spots can stain the metal).

If required or deemed necessary, you can disinfect stainless steel tools with a food safe sanitizer to eliminate harmful bacteria that could lead to contamination. Common disinfectants include 70% isopropyl alcohol or a chlorine-based solution. Follow manufacturer instructions for dilution and contact time.

Sterilization: As with plastic, sometimes sterilization is recommended or required as part of the cleaning process. An autoclave is highly effective and common sterilization method. It’s important that the tools are fully constructed of stainless steel without any non-metal parts, like rubber or plastic since the stainless steel will require settings specific to steel material. To ensure sterilization, follow suggested guidelines.

Drying: Dry stainless-steel tools with an air-dryer or wipe them thoroughly using a clean towel. This step will avoid possible staining, rusting or bacteria growth when storing.

Important Tool Cleaning Reminders

Always refer to tool supplier and chemical supplier recommendations and industry requirements/guidelines for specific cleaning agents, chemicals and autoclave methods appropriate for your types of tools. As an additional safeguard, test the cleaning products/procedures to ensure positive results. To avoid damaging your tools, do not use unapproved chemicals or scrubbers that are too abrasive. And, establish a regular protocol based on cleaning guidelines to maintain the sanitary condition of your tools.

Note: When receiving newly purchased tools, removing any stickers/label, making sure no adhesive remains. Any sticky residue can attract bacteria and unwanted debris. The same cleaning protocols outlined above should then be followed before the tools are entered into the food processing cycle.

Storing Your Tools

Proper tool storage is key to not only hygienic practices, but also the life and performance of the tools. Keeping tools well-organized in sanitary and protected areas of your facility will extend tool life and keep the tools within their designated areas -- both necessary in protecting your investment. Extreme heat or cold can damage or degrade the tool material (e.g. extreme cold can fracture plastic, damaging the tools and creating physical hazards), and high levels of humidity that don’t allow tools to dry or remain dry can encourage growth of microbial hazards.

The following storage criteria for storing/hanging tools are good guidelines to follow:

- ID clean storage areas with adequate space so they do not touch or come in contact with the wall or floor, reducing the risk of cross-contamination and additional wear and tear.

- Locate the tools in a cool and dry area (no direct sunlight or extreme heat) to avoid any rusting or deterioration, and allow the tools to thoroughly dry/stay dry.

- Make sure the “heads” of the tools are pointed down as a best practice.

- Use methods/products that are designed to allow for proper and efficient storage and hanging of tools. Important features include being easy to clean, offering adequate airflow, customizable and offering color-coding options.

Recommended storage products:

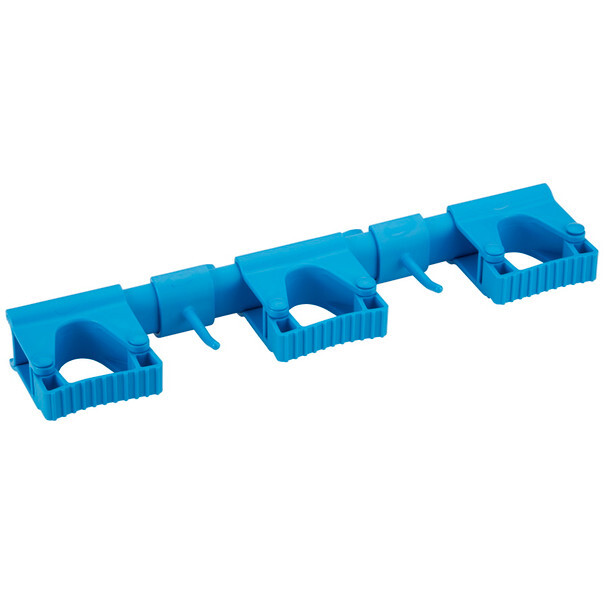

Hygienic Hi-Flex Wall Bracket System for 5-10 Tools - A color-coded, hygienic and modular wall bracket system that is easily to disassemble and clean.

![]()

Vikan Wall Bracket for Buckets & Pails - This bracket ensures optimal hygiene levels by allowing pails to hang upside down for drying or upright for storing ingredients.

Stainless Steel Wall Bracket for 6 Tools – This bracket features an ultra-hygienic design that can store up to 6 tools.

HyGo Mobile Cleaning Station - A mobile cleaning station/rolling sanitation cart. Ideal for organizing and transporting cleaning tools and heavy cleaning materials, including chemical containers.

Identifying When it’s Time to Replace Tools

Regular inspection of your tools is essential. Inspect your tools for any damage or visible wear before storing them in designated areas. Repair or replace any damaged tools immediately. Excessive wear can make tools difficult to thoroughly sanitize and create a safety hazard in your facility. Common indicators can include:

- Excessive scratching, abrasions, gouges or staining.

- Brush filaments that are missing, splayed/curling, bent or brittle.

- Discoloration.

- Broken, malfunctioning or ineffective parts.

Union Jack offers a convenient Replacement Parts section of our store to help you replace necessary parts without having to invest in the pieces that are still in good shape.

Excessive Wear in Food Safe Plastic Tools

Cracks or Breaks: Any cracks or breaks are a clear sign that replacement is necessary. These cracks can harbor bacteria, may lead to contamination and make the tools unsuitable for food handling.

Color Fading: If the tool color fades the color-coding benefits may be compromised and it may be difficult to identify which tool is used for, leading to unsanitary and /or improper use.

Surface Damage: It will be difficult for you to clean your tools with scratches and gouges. If not cleaned thoroughly, this will lead to bacteria growth.

Excessive Wear in Stainless Steel Tools

Corrosion: Despite being corrosion-resistant, rust can form in certain environments over time.

Dents or Bends: Tools that are bent or dented should be replaced because they won’t function properly and they may lead to contamination issues.

Final Thoughts on Tool Maintenance

Union Jack provides high quality tools that are designed to help meet FDA compliance and follow HACCP guidelines. By following tool maintenance and storage guidelines, you can ensure your tools are working effectively to maintain high standards of hygiene. Regularly clean and inspect your tools, and replace them when necessary to keep the food processing environment as safe and sanitary as possible. With proper care, your tools will perform at the highest level for a longer period of time, keeping your facility running smoothly. Explore Union Jack Tools and upgrade your food processing tools!

Recent Posts

-

Origin Story: The Baguette!

We find origin stories fascinating. And, while dreaming about the perfect baguette sandwich recently …Sep 16, 2025 -

Stress-Free Freight Deliveries with Union Jack

Let's face it -- ordering anything that ships via freight can be super challenging and frustrating. …Aug 14, 2025 -

Preventing Listeria in your Brewery or Food Processing Drainage System

It is estimated that 30% of drains in food and beverage production facilities test positive for List …Jul 23, 2025