3 New Color-Coding Options to Enhance Your GMPs/HACCP Plan

Union Jack now offers our most popular cleaning and food processing tools in three new colors. Our FDA-compliant and hygienically designed shovels, scoops, brushes, silicon bands, buckets /lids,scrapers and wall brackets are now available in Brown, Lime and Gray. These 22 products are currently available in the following 12 colors: Pink, Green, Blue, Red, White, Yellow, Orange, Purple, Black, Brown, Lime and Gray.

There are currently no regulations requiring particular color choices for your GMPs / HACCP plans, but certain colors are typically chosen for both practical and helpful purposes. For increased food safety, it’s recommended to choose a color that contrasts clearly with the food produced. Choose one color for the cleaning and food handling tools that come into contact with food, and a different color for equipment and tools that do not. Also, select one particular color for cleaning drains.

Consider

- More common colors like green, blue, red, white and yellow for larger color coded zones where many different kinds of cleaning equipment and food handling tools are needed (green for non food contact, e.g. floors, and blue for food contact (few foods are blue)

- Less common colors like pink, orange, purple and lime for high risk / allergen control in smaller areas that use fewer cleaning equipment and food handling tools (color-coded bands in these colors on more standard colored tools is also a good option)

- More discrete, subtle colors like brown and gray for highly visible areas like hallway and corridors

- Brown as a good replacement for wooden products

- Black for drains and other heavily soiled area (doesn’t show dirt)

Benefit of Color-Coding

- Minimizes risk of cross-contact and cross-contamination, product rejection/recall, number of tools required, costs to replace equipment, and language-based misunderstandings

- Improves speed of processes and service life of product

- Promotes a culture of safety, and visually and orderly/safety-focused work areas

Color-Coding Planning Considerations

- Hazard Analysis – HACCP plan

- Allergens - assign a specific color code to the tools and equipment that come into contact with each allergen

- Zones - facility and production line level

- Processes

Helpful Hints

- Use contrasting colors to easily ID any small pieces of tools or bristles

- Use colors that are color-blind friendly (high contrast colors/shades)

- Avoid mixing colors on the tools (use the same color for handles and heads)

- Keep your color-coding simple and logical; don’t use too many colors

- Color-code the tools according to the storage areas (wall brackets, shadow boards)

- Use good signage to support your color-coding

- Fully color-code and communicate the plan clearly

- Follow through with the plan and set up a maintenance plan to follow

Check out our additional Color-Coding blog topics at Understanding Color-Coding Basics - FSMA / HACCP Compliance and 7 Steps to Color-Coding in Your Brewery

If you need help finding colors for a particular product, want samples, or would like to setup PO terms, just reach out to us!

Union Jack -- Your Partner in FSMA /HACCP Compliance

Recent Posts

-

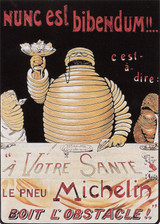

The Origin of the Michelin Guide

From a little red guide book to an iconic standard in international fine dining, have you ever w …Mar 10, 2024 -

Make Color-Coding Your Resolution

Color-coding is a simple way to have a big impact on your facility’s food safety, sanitation and co …Jan 16, 2024 -

Why EPDM Transfer Hoses are a Great Choice for your Brewery

EPDM stands for ethylene propylene diene monomer. It’s a synthetic rubber that has quickly gained t …Jun 14, 2023